Committed to creating the world's most reliable resistors

Shida resistors have passed multiple national level certifications worldwide

Order Hotline:086-755-88822893 Email:

Committed to creating the world's most reliable resistors

Shida resistors have passed multiple national level certifications worldwide

Order Hotline:086-755-88822893 Email:

Date : 2025-05-16Source: Unknown

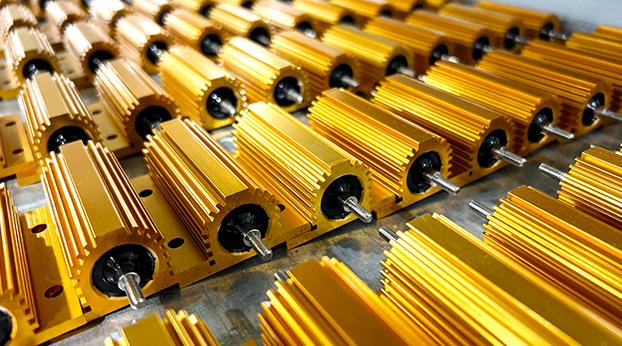

Aluminum shell resistor

Aluminum shell resistor, the shell is made of aluminum alloy (gold aluminum shell), with heat dissipation grooves on the surface, small volume, high power, high temperature resistance, strong overload capacity, weather resistance, high precision, standard low inductance resistance, high stability, strong architecture, and good flexibility. Multiple combination options are available for mechanical protection and easy installation and use.

The good plasticity of aluminum metal also allows aluminum shell resistors to have better dimensional changes to adapt to installation space. The filling material of the aluminum shell resistor is insulating silicide, which allows it to absorb a certain amount of heat instantly. Reaching several times the power of the resistor in an instant.

The function of the aluminum shell in an aluminum shell resistor is cooling. Aluminum metal has excellent thermal conductivity and can quickly transfer the heat generated when the resistor conducts electricity to the surface of the resistor, and continuously dissipate the heat through the air. The surface of the aluminum shell is designed with more heat dissipation grooves, which increases the heat dissipation surface area and enhances the heat dissipation capacity.

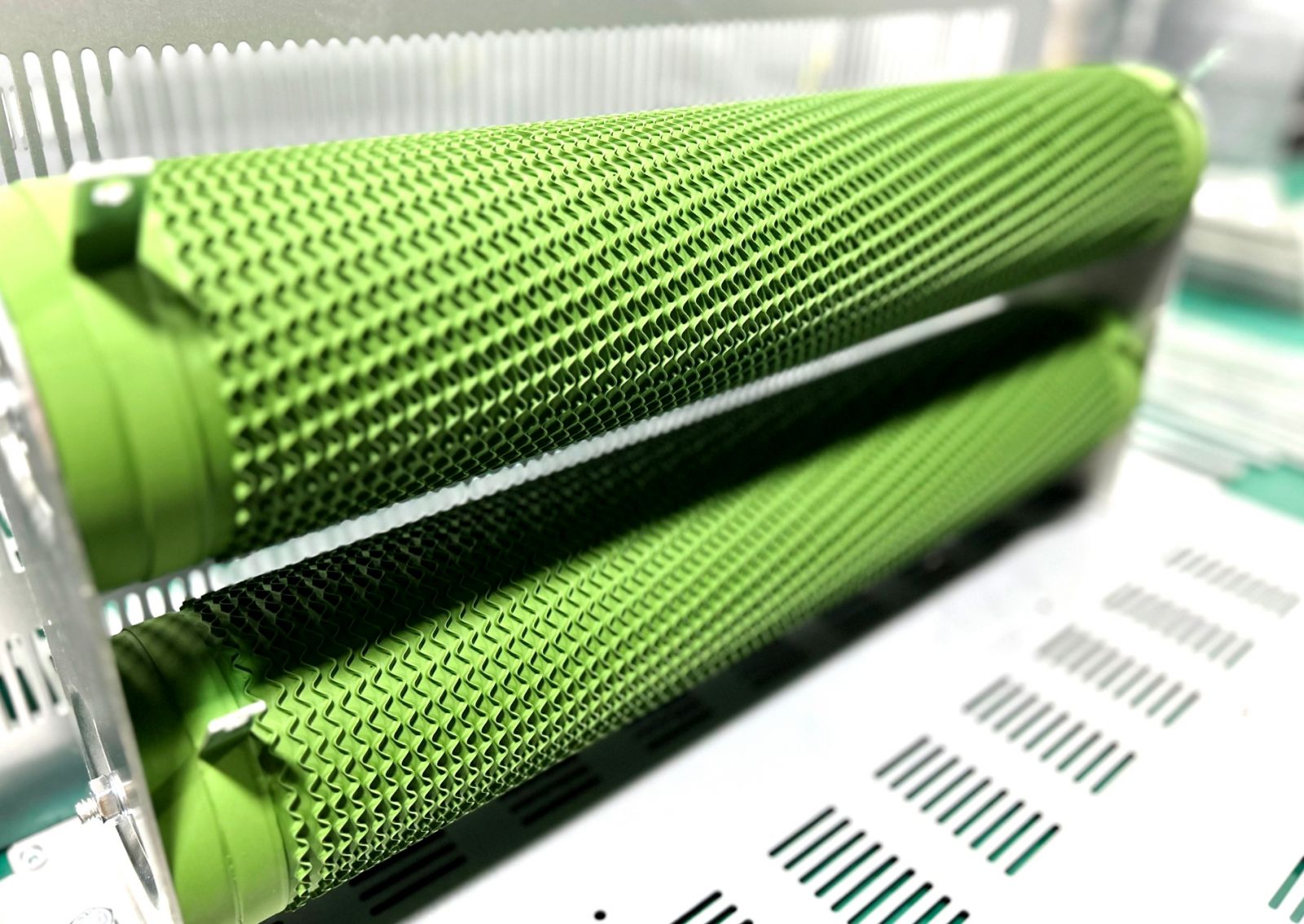

Wire-wound resistor

The winding resistor adopts ceramic tube as the skeleton, and alloy resistance wire is uniformly wound on the skeleton. The surface is coated with high temperature resistant insulation coating, which is easy to install.

The low resistance value of the winding resistor is 20 Ω -50 Ω, which can press the resistance wire into a corrugated shape and stand on the ceramic substrate, thereby increasing the usable area of the winding and having better heat dissipation performance.

Performance difference

Aluminum shell resistors, due to the presence of fillers that can absorb heat, will have a lower surface temperature than wound resistors of the same power after being energized for 1 second

In the case of long-term power on, the advantages of wire wound resistors are very detailed. Due to the fact that the resistance wires of wire wound resistors can almost directly contact the air (with only insulating paint as the spacer), the heat dissipation ability of wire wound resistors is superior to that of aluminum shell resistors when powered on for a long time

In the structure of aluminum shell resistors, there is an insulation layer between the resistance wire and the aluminum shell, and the insulation performance can reach a leakage current of less than 2mA between 1500V-4000V according to different requirements. The insulation performance is very good

The structure of a wound resistor is a layer of insulating paint on top of the resistance wire, with insulation performance below 500V, and the insulation performance is unreliable and not suitable for exposure in touchable positions

The architecture of aluminum shell resistors is stronger and has better vibration resistance compared to wire wound resistor architecture

Aluminum shell resistors have a smaller volume compared to wire wound resistors, good insulation performance, stronger architecture, and are suitable for working in more complex environments

The cost of winding resistors with the same power should be detailed and lower than that of aluminum shell resistors

Overall comparison: Aluminum shell resistors have advantages in instant electrification, insulation performance, structural stability, and installation convenience. Wire wound resistors have significant advantages in long-term electrical performance.

We are committed to building the most

reliabler resistors in the world